SELECTED COMPANIES TRUST ALEGER

REDUCE PRODUCT DEVELOPMENT TIMES AND COSTS

Gain competitive advantage through digital product development. Delight customers with fast response times by creating virtual prototypes in the shortest possible time. Product developers will be thrilled, because the advantages are obvious:

FULL FLEXIBILITY

Respond immediately to innovations and changing requirements.

SHORTEN DEVELOPMENT TIMES

Simulate prototypes within days to estimate feasibility and costs in a timely manner.

OPTIMIZED PRODUCT DEVELOPMENT

Reduce material usage by up to 37%, taking all parameters into account.

REDUCE ERRORS

Reduce coordination efforts between tools and teams across the enterprise by up to 30%.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFROM DESIGN TO VIRTUAL PROTOTYPING

The platform for digital product development integrates a wide variety of development tools from departments such as construction, design or simulation. The special feature: target parameters such as price, higher speed or more performance can thus be defined and specified in advance. Based on this, the calculation is made, taking into account all the parameters of the different tools. Thus, answers to questions such as feasibility, costs, or product behavior can be provided quickly in meaningful reports.

APPLICATION AREAS OF DIGITAL PRODUCT DEVELOPMENT

AUTOMOTIVE

Benefit from the comprehensive model library. Dozens of stator and rotor geometries, different interfaces to 2D and 3D FE tools, post-processing functions, and much more.

OEMS

Your customers want to know quickly and reliably whether you can realize this or that application? With virtual prototyping, you have all the important data and statements ready in the shortest possible time.

PLANT CONSTRUCTION

Set the tone and develop faster, better and more cost-effectively. Product development 4.0 means networking tools and teams across departments and making the most of digital development

FINISHING

With virtual protoyping, components can be simulated in different environments and material applications. This enables you to provide reliable answers more quickly.

HOW DOES DIGITAL PRODUCT DEVELOPMENT WORK?

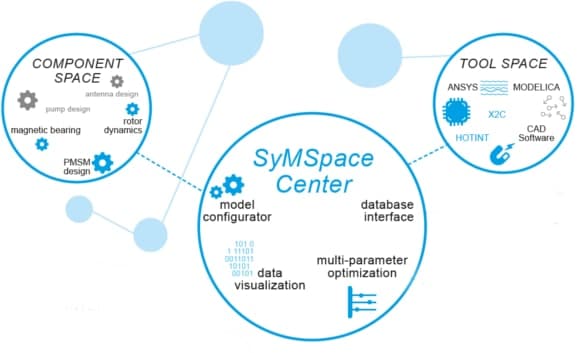

The central product development platform consists of 3 areas that are networked with each other:

- Component Space (model library): Here, digital models of mechatronic systems and components are available to the user. It should be mentioned: This model library is constantly expanding.

- Tool Space: This area includes many existing interfaces to different software programs for design, calculation and simulation (SolidWorks, FEMM, Mathlab, Ansys, HotInt, etc…)

- SyMSpace Center: Here, the digital models from the model library are freely and flexibly linked with the software programs from Tool Space at the click of a mouse.

PRODUCT DEVELOPMENT 4.0 WITH VIRTUAL PROTOTYPING

By simply linking modules and development tools, it is also possible to configure an automated development loop – with continuous adaptation of the design.

In addition, depending on the size of the development loop and when the results should be available, you can easily adjust computing power (local CPU, cloud) via mouse click.

Instead of manual reconciliation and data transfer between tools and departments, the virtual product development platform thus delivers all optimized target parameters easily and quickly. This means that you have efficiently networked all the components for virtual prototyping, and nothing more stands in the way of product development 4.0

MODERNIZING LEARNING PROCESSES WITH MOBILE MAINTENANCE

EXPANDABLE MODEL LIBRARY

The model library is constantly being expanded by us, our users, and perhaps soon by you.

VARIOUS TOOLS

Stay with your proven software through a variety of existing interfaces (Creo, python, CAD, ANSYS HOTINT, Java, X2C, FEMM, and many more).

SERVER IMPLEMENTATION

We know about the sensitivity of development files. Of course, the platform can be run on your servers.

EXTERNAL SIMULATION CAPACITY

Run simulations flexibly and quickly via provisioned servers without having to build up your own resources or wait for results.

PAY-PER-USE MODELS

Through our attractive Pay-Per-Use model, you only pay for what you actually use.

DOCUMENTATION AND EVALUATION

Directly reuse the automated evaluations and complete documentation of the post-processing.